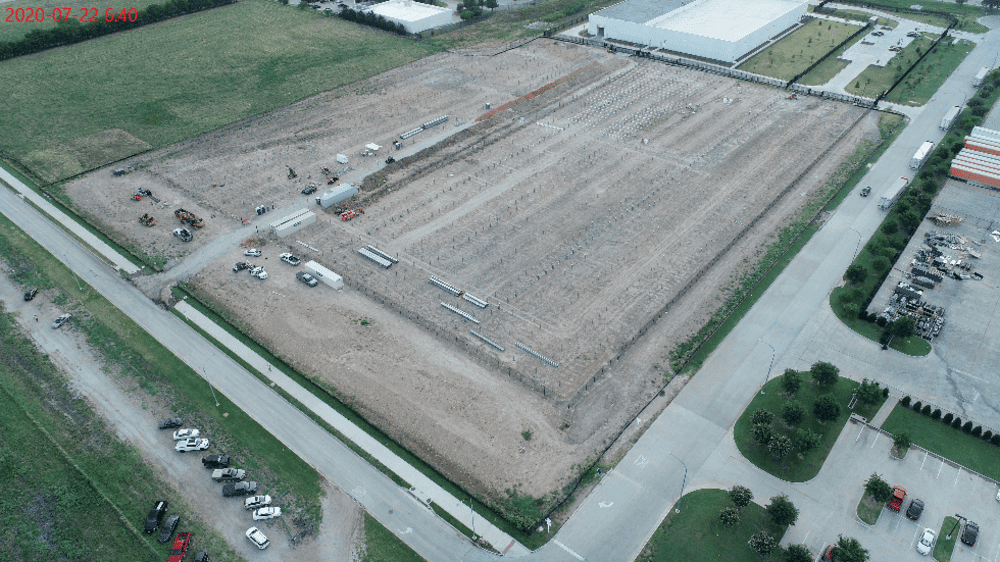

The Client retained Telios as the MEP engineer of record for a new 700-acre corporate campus, including a nearby 20 acres for their private data center in North Texas. The data center master plan included constructing a 3 MW data hall on 10 acres in the first phase and reserving the remaining 10 acres for data center expansion at a future, unknown date. However, the land values in the project area command a premium, thus presenting a significant tax burden the client was struggling to address. Telios offered a solution: leverage the land for a PV plant that feeds directly into the data center, leverage the ITC and depreciation schedule to lower taxes and energy costs rather than raise them, and construct the financial proforma to allow for PV relocation should the land be needed for expansion before PV end-of-life. The net result is a 100% PV-powered data center with extremely favorable economics. It is the definition of a win-win energy development.Telios provided turnkey project development including financial analysis, all EPC services, interconnection management, commissioning, and ongoing O&M support. The PV design totals 3.5 MWdc using Seraphim 400W bifacial modules, GameChange single-axis trackers, and Sungrow 60 kW string inverters. AC power is aggregated into three (3) separate blocks of 960 kWac each, allowing the data center’s critical distribution systems to be fed equally. This topology also limits the net power that can be exported at any single point of interconnection, thereby eliminating complicated protection schemes, and significantly reducing interconnection costs. The tracker system maximizes energy production by adjusting the panel position throughout the day to optimize the balance of direct and diffuse irradiance. Bifacial energy production should exceed 5% over baseline in a typical year. The system was designed to maximize the annual kWh produced per kW of installed capacity, netting an 8-year payback through direct consumption reduction and offsetting peak demand charges.

Confidential Financial Client Solar Project

Location

North Texas

Size

20 Acres, Data Center: 50,000 SF / 3 MW, Solar Farm: 3.5 MWdc

Project Highlights

3.5 MW Single-Axis Trackers , Net Power Utility Export, Three-Point Tie-In to Data Center 480V Distribution, Behind the Meter

Services Provided

Turnkey Project Development, Engineering & SCADA, Interconnection, Permitting, Procurement, Construction, Commissioning, O&M Support, Annual Maintenance and Operations

The Client retained Telios as the MEP engineer of record for a new 700-acre corporate campus, including a nearby 20 acres for their private data center in North Texas. The data center master plan included constructing a 3 MW data hall on 10 acres in the first phase and reserving the remaining 10 acres for data center expansion at a future, unknown date. However, the land values in the project area command a premium, thus presenting a significant tax burden the client was struggling to address. Telios offered a solution: leverage the land for a PV plant that feeds directly into the data center, leverage the ITC and depreciation schedule to lower taxes and energy costs rather than raise them, and construct the financial proforma to allow for PV relocation should the land be needed for expansion before PV end-of-life. The net result is a 100% PV-powered data center with extremely favorable economics. It is the definition of a win-win energy development.Telios provided turnkey project development including financial analysis, all EPC services, interconnection management, commissioning, and ongoing O&M support. The PV design totals 3.5 MWdc using Seraphim 400W bifacial modules, GameChange single-axis trackers, and Sungrow 60 kW string inverters. AC power is aggregated into three (3) separate blocks of 960 kWac each, allowing the data center’s critical distribution systems to be fed equally. This topology also limits the net power that can be exported at any single point of interconnection, thereby eliminating complicated protection schemes, and significantly reducing interconnection costs. The tracker system maximizes energy production by adjusting the panel position throughout the day to optimize the balance of direct and diffuse irradiance. Bifacial energy production should exceed 5% over baseline in a typical year. The system was designed to maximize the annual kWh produced per kW of installed capacity, netting an 8-year payback through direct consumption reduction and offsetting peak demand charges.

Telios Construction offers custom-built data and communication cabinets, which maximize connectivity and minimize technology storage requirements.