1 score and eleven years ago, I began my career in MEP engineering in Houston.

I took my first step off the plane and onto the terminal bridge and was immediately assaulted by the heat and humidity on my face. My first thought as a new mechanical engineer was, “Job security!”

My first experiences in the office were what I was expecting. AutoCAD had barely entered the office environment and did not have any functionality beyond putting lines on paper. We were still drawing some projects by hand on vellum and details were photocopied onto ‘sticky-backs’ by a Xerox machine and stuck to vellum sheets. The main communication methods between offices were desk phones, facsimiles, US mail, and Couriers. Nobody had cell phones and office networks, and the internet was still in early development.

Within the office, we passed files back and forth by 3.5” floppy discs that could barely hold a megabyte of information and site visits were done by pen and paper. Everything was sketched or written down. My office used a camera with film to document electrical panel schedules. However, that was novel because developing the film was expensive and took several days to get back. Digital cameras did not exist for many more years into my career and the photo quality was not great initially.

Building designs and MEP systems were not complicated. HVAC systems were controlled mostly by compressed air blowing through a network of tubes and pipes throughout the building. The lighting was dull and relied upon mercury-laden fluorescent tubes and heat-producing incandescent lamps. Plumbing fixtures used water like a 1970 gas guzzler and refrigerants poked holes in the earth’s atmosphere.

Although energy use was an ongoing consideration it was not paramount in our designs. In fact, ice storage was a novel design that was pursued at the time but did not even save energy! It shifted the energy use of the system to the evening to save on energy costs, but it used more energy than a conventional system at the time and it was considered state of the art.

Over time, the following items gained importance and MEP engineering changed significantly and adapted.

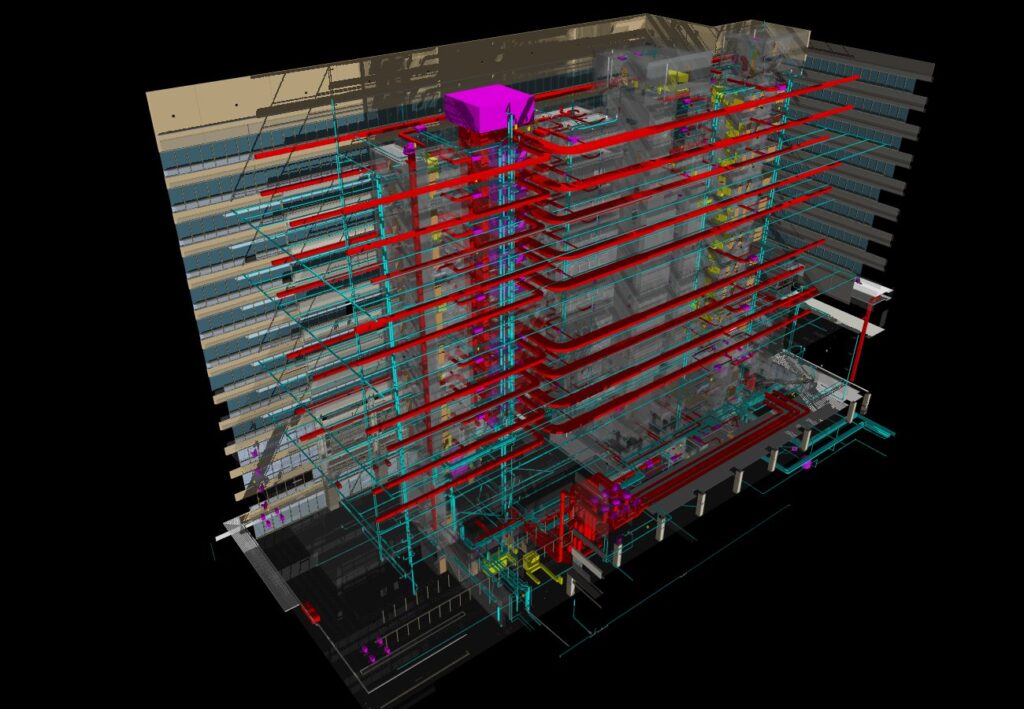

- Efficient 3D design tools with complex analytics took over the industry and significantly changed how engineers designed and developed their projects.

- Energy and water efficiency increased and led engineers down the path of designing with resource conservation in mind.

- Further practices in sustainability and refrigerant management helped to protect our atmosphere and environment.

- HVAC systems became more precise and dependable giving occupants’ greater control over temperature regulation.

- Lighting quality improved allowing uniform light levels, accurate color rendering, and limiting screen glare

- Legionella control in water systems improved with several innovations allowing plumbing engineers to design safer systems.

31 years later, many things have changed for the better. Everything has gone digital, and information is driving all decisions. The emergence of BIM (Building Information Modeling) has allowed MEP engineers to help their clients visualize their projects in 3D giving them a clearer understanding of the final concept. BIM has allowed for faster design, better coordination among building elements, and decreased construction costs and durations. Design and construction teams have left their traditional silos in favor of more interactive and collaborative working relationships.

- Our success will be decided upon by the quality of our work and our valued relationships.

- Heat and humidity will still require mechanical engineers to make it bearable.