Efficient and sustainable building design relies heavily on the meticulous planning and execution of Mechanical, Electrical, and Plumbing (MEP) engineering systems. The MEP planning process involves a systematic approach to ensure the seamless integration of these critical systems within a construction project. Here’s an overview of the key stages in the MEP engineering planning process.

The MEP engineering planning process begins with a thorough understanding of the project’s scope, objectives, and specific requirements. Collaborative discussions between architects, structural engineers, and MEP specialists help establish the foundation for successful integration of mechanical, electrical, and plumbing systems.

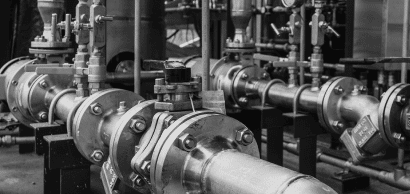

A comprehensive evaluation of the construction site is essential to gather data on environmental conditions, spatial constraints, and local regulations. Site assessments inform decisions related to system placement, energy efficiency, and compliance with building codes.

In this phase, engineers develop the initial concept for the MEP systems. This includes layout and sizing of mechanical rooms, placement of electrical panels, and routing of plumbing systems. Collaboration with architects and other stakeholders ensures that the MEP systems align seamlessly with the overall building design.

MEP engineers carefully select the appropriate systems and components based on factors such as energy efficiency, sustainability goals, and the specific needs of the building occupants. This involves choosing HVAC systems, lighting fixtures, plumbing fixtures, and other elements that contribute to the overall functionality and performance of the building.

Engineers create detailed drawings and specifications that provide contractors with precise instructions for system installation. This includes layout plans, equipment specifications, load calculations, and other technical documents necessary for construction.

Coordination between different MEP disciplines is crucial to avoid conflicts and ensure smooth integration. Clash detection software is often used to identify and resolve potential clashes between various systems, preventing issues during the construction phase.

MEP engineers conduct energy simulations to assess the performance of the building’s systems under different conditions. Optimization strategies are implemented to enhance energy efficiency, reduce environmental impact, and meet sustainability goals.

Accurate cost estimation is vital for project budgeting and financial planning. MEP engineers work closely with project managers to provide detailed cost breakdowns, taking into account materials, labor, and equipment.

Throughout the construction phase, MEP engineers provide support to ensure that the installation of systems adheres to design specifications. Regular site visits, inspections, and collaboration with contractors contribute to the successful implementation of MEP systems.

The final stage involves the commissioning of MEP systems, where thorough testing and verification are conducted to ensure optimal performance. After successful commissioning, the systems are handed over to the building owner, and documentation is provided for ongoing maintenance.

A well-executed MEP engineering planning process is essential for the creation of high-performance, sustainable, and comfortable buildings that meet the needs of occupants while adhering to industry standards and regulations.